Solve Problems, Not Symptoms | APT

Solve Problems, Not Symptoms | APT

Problems vs. Symptoms

Here at APT, we strive to solve problems, not treat symptoms. Just like when you visit a doctor, the symptoms are clues to discovering the underlying disease or problem. Rarely does a successful doctor just treat the symptom.

For instance, if your problem is a leaky roof…

- Getting a bucket to catch the leak is treating the SYMPTOM

- Fixing the roof is solving the underlying PROBLEM

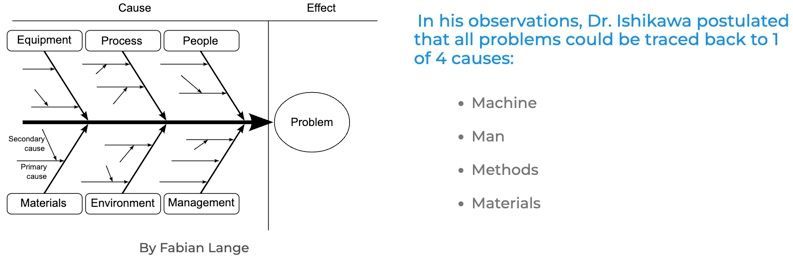

Ishikawa Fishbone Diagrams are a great way to visualize the tendency to focus on symptoms (see figure below). Japanese quality engineer Dr. Ishikawa applied statistical quality control methods (like those introduced by Deming in Japan after WWII) to manufacturing problems. The pictures he created resembled the head of a fish. The root causes and contributing factors built the bones of the fish’s skeleton. His findings apply both to manufacturing and to business in general. In fact, there are only a few basic root causes of production interruptions, despite the number of problems faced.

He found that these four elements were responsible for everything that happened. For example, our leaking roof scenario.

He would attribute the leaking roof to:

- (a) vibration of the AHU (MACHINE) on the roof

- (b) Lack of maintenance (MAN) on the roof AHU

- (c) Improper installation (METHODS) of the AHU roof sleepers

- (d) Incorrectly specified sealant (MATERIALS) on the roofing system.

The value of this observation and tool lies in the fact that each of the root cause categories should address any problem (i.e., leaking roof). Even the biggest bucket (even for a minor problem) only addresses the symptoms.

Don’t wait to Solve Problems

APT realizes that all problems have several root causes. Furthermore, we ensure that these root causes are addressed in every solution we propose. Simply put, you need to think about your equipment inventory (MACHINE), your training and certification process (MAN), your standard operating procedures (METHODS), and your critical spare parts (MATERIALS).

Many organizations spend a lot of time and money on equipment installations, maintenance, and repair (after all, it’s part of your O&M budget!). But very little on training, documentation, and essential spare parts. Until the other root causes are addressed, you will continue to have problems. The success of any organization or job depends on the ability of the company to provide customers with resources that address all four of these basic root causes.

Our solutions include visual elements that address the four common root causes of problems. I hope you will consider using the Ishikawa Fishbone Diagram tool in your next root cause analysis and when you propose your next capital budget to management. I welcome anyone who can share their real-world experience with this tool or similar tools as well.

ANDY TAYLOR | APT CHIEF EXECUTIVE OFFICER

Contact