Electrical Safety Violations | Top 10 Countdown

Electrical Safety Violations | Top 10 Countdown

A safe working environment is vital and requires the participation of all parties interacting with your facility. Unfortunately, cutting corners to speed up a project or task is common, often resulting in electrical safety violations.

While an electrical safety violation may not appear serious, in reality, it is an accident waiting to happen. So, let’s countdown the top 10 electrical safety violations in any facility.

Electrical Safety Violations | Top 10 Countdown

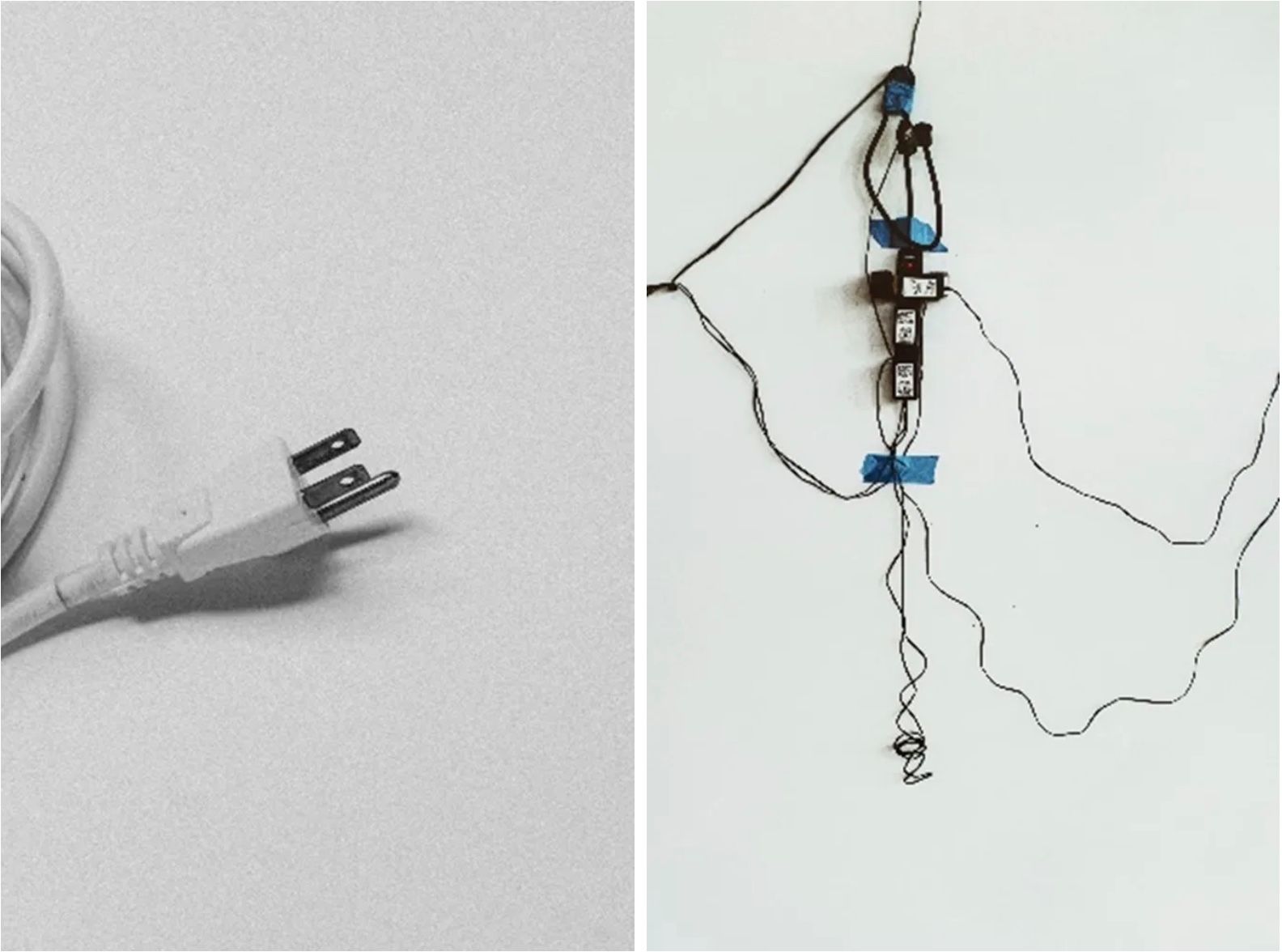

10. Failure to remove obsolete electrical or communications wires and equipment

Over time, your facility will change to accommodate new employees, increase productivity, and more. As a result, you may need to modify your electrical equipment and communications wiring.

To prevent them from becoming a safety hazard, you must remove all electrical wiring and equipment no longer in use. In short, this process requires removing or installing wiring and gear to maintain electrical safety and codes. Wires are often visible when inspecting electrical systems in a building that has undergone renovation. So, consider keeping your facility free from obsolete telephone lines and data cables. Ideally, you want to remove all unnecessary wires and equipment from your facility.

9. Inadequate circuit identification and labeling

Proper labeling of all equipment and circuits from the source to the device is essential in maintaining electrical safety at your facility. But, it is challenging to repair or change anything within your electrical system without adequately identifying electrical circuits from the panel schedules and device labels. In addition, labeling needs to be permanent and withstand its environment.

8. Missing or discontinuous electrical wiring paths to ground

Equipment grounding is vital for maintaining safe electrical systems. If there is no ground connection to the electrical equipment at your location or any broken power paths exist, your workers are at risk. In addition, grounding electrical equipment reduces your facility’s risk of electrical fires and electrocution.

However, it is important to note that electrical equipment can instantly become dangerous due to harsh conditions or mishandling even when the power system is grounded correctly. Workers can sustain burns or die if fault currents flow through their bodies.

Check out OSHA’s list below on how to avoid hazards:

- Ground all power supply systems, electrical circuits, and electrical equipment

- Frequently inspect electrical systems to ensure that the path to the ground is continuous.

- Visually inspect all electrical equipment before use. Take any defective equipment out of service

- Do not remove ground prongs from a cord and plug connected equipment or extension cords

- Use double-insulated tools and equipment, distinctively marked.

- Ground all exposed metal parts of equipment

- Ground metal parts of the following non-electrical equipment, as specified by the OSHA standard [29 CFR 1926.404(f)(7)(v)]:

- Frames and tracks of electrically operated cranes

- Frames of non-electrically driven elevator cars to which electric conductors are attached

- Hand-operated metal shifting ropes or cables of electric elevators

- Metal partitions, grillwork, and similar metal enclosures around equipment of over 1kV between conductors

7. Misuse or incompatibility of electrical equipment

A variety of manufacturers produce electrical equipment. A manufacturer designs equipment and components to be compatible with its own product line. Even if a circuit breaker fits into another brand’s equipment, it may not always be safe for installation.

Unless expressly stated otherwise, different manufacturers’ products are not interchangeable.

6. Improper use of Flexible cords/extension cords

Initially, flexible cords may appear to provide a simple resolution to an electrical problem. However, unless the cord installation meets NEC requirements and obtains approval, it poses an electrical hazard. For instance, extension cords meant solely for temporary use require removal once they are no longer necessary.

5. Inaccurate Arc Flash & Coordination Studies Labeling for PPE requirements

Per OSHA, arc flash labels must identify:

- Nominal voltage,

- Arc flash boundary

- Personal Protective Equipment (PPE)

Creating these labels involves the analysis of electrical systems, known as Arc Flash and Coordination studies.

Arc Flash studies determine the energy released in an electrical phase to phase or phase to ground fault.

Coordination studies, on the other hand, use software models of every manufacturer of relays, circuit breakers, fuses, transformers, and cables. These models plot the time versus current curve of fault current to adjust the long time, short time, instantaneous, and ground fault settings. Properly coordinated protective equipment eliminates nuisance tripping while selectively clearing electrical faults at the closest possible protective device to the fault.

Updates of these studies must occur every five years or following any changes to the electrical system.

4. Inaccurate As Build electrical drawings updates (floor plans/ lighting plans/one-line diagrams/panel schedules)

Many facilities neglect to include floor plans, lighting plans, one-line diagrams, and panel schedules in their facilities, causing confusion about what and how the electrical system works. Your facility’s latest build documents should always incorporate any changes as they occur.

3. Insufficient GFCI Protection

The NEC requires ground fault circuit protection for all electrical equipment 150V to the ground but not exceeding 600V main circuit protection for 1000 amps or more. In addition, bathrooms, garages, outdoor sockets, crawl spaces, basements, and anything within six feet of a sink or water source require GFCI circuit protection.

Therefore, it is critical to test and maintain GFCI equipment annually to ensure appropriate repairs or replacements occur when necessary. Temporary cords should also be used with GFCI protection as a safety feature to prevent electrocution.

2. Improper electrical room or panel location storage

Many facilities suffer from overwhelming storage issues. Electrical rooms and panel locations must meet specific dimension requirements to ensure the safe operation and maintenance of the equipment. Per NEC standards, there is typically open space within electrical equipment rooms.

Unfortunately, many people use this area for extra storage due to its convenience. However, regulations exist for a reason. Storing items in the open space is a major electrical safety violation. You create a highly hazardous working environment, endangering your workers and facility as a result.

1. Insufficient Lockout/Tagout Training

Finally, the number one safety violation for all electrical facilities is the proper use of Lock Out Tag Out and training for all personnel working on the electrical system. In short, working on energized electrical equipment without following LOTO procedures that every team member clearly understands creates the most significant potential for injury or death. Therefore, OSHA requires employers to train each employee, ensuring they understand and are capable of performing hazardous energy control procedures.

Workers must:

- Understand the purpose and function of the energy control program

- Have the knowledge and skills to apply, use, and remove energy control devices safely

Worker safety depends upon proper lockout/tagout (LOTO) practices. Check out the OSHA standard for The Control of Hazardous Energy (Lockout/Tagout) (29 CFR 1910.147) for more information.

APT 4 Electrical Safety Solutions

Keeping your employees and facility safe is a top priority. Modern technology, energy code requirements, poor power quality, and high energy costs make it more critical than ever to maintain the health of your facility’s power equipment. But, don’t worry, you aren’t in this alone. APT delivers a turnkey solution. Many of our clients are seeking to reduce the risk of electrical failures. At APT, we take it to the next level, engineering, installing services, start-up, and maintenance of power equipment. Above all, we understand how your electrical system operates, and what needs to be done to ensure the safety of your employees and facility.

Brian Curnutt | APT Field Service Manager

Contact